Installing a boiler is a popular solution when looking to put in a new house heating system or upgrade an old one.

On average, installing a boiler costs $4,500 – 8,000 depending on the type of boiler you select, including professional labor and the device itself.

Boiler Replacement Cost

Standard gas or oil boilers, without a tankless or indirect hot water feature, will usually have 82-86% AFUE efficiency rating and will cost $4,690 – $7,200 to install (oil boiler being about $500 more expensive than gas, as it needs an Oil Burner – an expensive part, which is not needed on the gas boiler.

Standard / conventional boilers are ALL “chimney vented”, and need either a chimney, or an insulated metal vent pipe (metal chimney) going up above your roof line. It’s important to have this vent pipe, and to have it above roof line by about 24-36″ to have a natural air draft pull hot exhaust gases. Otherwise that exhaust gas may end up in your home, which very bad!

Our cost estimate does not include a steel, insulated exhaust pipe – only a flue connection going into the chimney.

How Much Does a Condensing Boiler Cost?

There are also “combi” (or combination) boilers that function like both a water heater and a boiler. Combi boilers are usually much smaller than other boilers, and a lot more efficient, coming in at around 95% AFUE rating.

The cost tends to range from $2300 to $3700 (for equipment only). Installing a Combi Condensing Boiler will cost around $5,680 – $8,730 in a 2000 sq.ft. home.

These prices do not include installation of radiators / baseboards. If you already have a boiler in your home, usually you do not need new radiators, unless you have a steam boiler, and want to switch to a forced-hot-water system.

In some cases if you have a cold room, you may add 4-8 feet of baseboard (which may cost around $700-1000 (which includes draining the water loops, tying in a new radiator, refilling the water and bleeding the air from the pipes), to increase a heat output in that particular room.

Keep in mind, since hot water runs in a loop, that heat, which you add to one room, is taken out from another room.

Installing new baseboard radiators in a whole house (about 2000 s. f.) will cost around $4500-$6000, for labor and materials.

It is critical to have your heating contractor do proper heat load calculation in each room, to accurately calculate length of baseboard radiators needed. Otherwise your system will be off balance.

h2>It’s a Boiler – not a Water Heater

Boilers and water heaters are two different devices. Water heaters heat water for domestic hot water usage to your temperature setting (which is typically not more than 120-130°F to prevent scalding), and then provide your house with hot water.

This is the hot water that comes out of your shower, and sink faucets throughout the house. The water heater takes cold water, heats it up, and sends hot water out for hot water usage.

A boiler, on the other hand, is usually responsible for heating your house. Heat is more easily transferred as steam which is then radiated into the air in the house. The boiler may produce either hot water or steam depending on the type of boiler it is.

Hot water heaters have an inlet of fresh cold water, and then they send the water to a faucet and out of the water system or down the drain.

Boilers are generally connected to closed loop systems. A closed loop system heats up the cold water, sends it through the house as steam (or hot water), and then repeats the same water after it has cooled down.

Some Boilers Use Hot Water

As I mentioned before, boilers do not always use steam. Sometimes boilers use hot water. The difference between water boilers and steam boilers is which part of the system is more efficient.

A hot water boiler uses more energy to transport the water, but less energy heating it up. A steam boiler uses more energy heating up the water, but less energy transporting it.

It is more efficient to use a steam boiler in a larger house (or industry) where there is more concern for transport. Steam would also generally be more effective in a colder climate or in a house with less insulation.

Hot water boilers also require pumps to send the water throughout the house, whereas steam boilers allow the steam to expand and flow by itself filling up the pipes. The steam then condenses to water and is carried back to the boiler by gravity.

Price of Steam Boiler vs Hot Water Boiler

Steam boilers have higher low end costs than hot water boilers. Steam boilers start at around $2,500 and hot water boilers start at around $1,200.

| Steam Boilers | Hot Water Boilers | |

| Low End | 2500 | 1200 |

| Average | 4000 | 5677 |

| High End | 7500 | 8000 |

How Does a Boiler Work?

In order to heat the water piped through your radiators and heating system the boiler uses a heat exchanger. The heat exchanger is something that moves heat from one fluid to another while always keeping the two fluids separate. These fluids could be any liquid or gas; in a boiler they are normally water or steam.

Water (or steam) circulating through the house is returned to the boiler and pushed through a pipe (often copper which is highly conductive and not reactive with steam) while the burners are lit.

The burners heat the water while it is running through the pipes. In order to maximize the heating process, the pipe bends back and forth to maximize the area in contact with both the heat and the heated fluid (likely water).

How Is the Fire Provided

In all cases the boiler is heating water, and the energy to heat the water must come from fuel. There are a number of different popular fuels including natural Natural Gas, Liquid Propane (LP), Fuel Oil, or electricity (actually electricity is not a fuel – but it is the product of another (huge) boiler in the power plant generating electricity).

Oil boilers were once very common. An ash-free combustion, they are cleaner than coal or wood. Oil is transported by trucks. About 85% of the total US heating oil consumption is in the northeast, in New York, Pennsylvania, and New England.

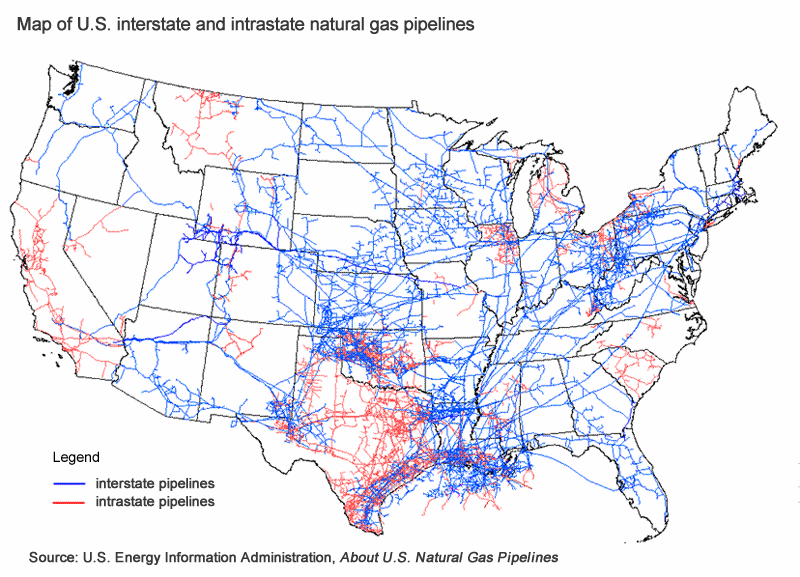

Natural Gas is piped throughout the United States.

Natural Gas is the most common, popular and cost efficient heating fuel in the US. If your house is close to the pipeline it can be piped directly into your home. If the pipeline is not close (geographically), then natural gas can be brought in liquid form via trucks.

Natural gas is produced in many states, with Texas, Oklahoma, and Louisiana consistently ranked within the top 5 for production. The government reports the top five states in production also include Pennsylvania and Ohio.

Natural Gas Production in the US

| State | % Produced |

| Texas | 23.90% |

| Pennsylvania | 20.00% |

| Louisiana | 9.30% |

| Oklahoma | 8.50% |

| Ohio | 7.70% |

It may be interesting to note that the top five states in natural gas usage are not the same five.

Natural Gas Consumption in the US

| State | % Used |

| Texas | 14.90% |

| California | 6.90% |

| Louisiana | 6.00% |

| Pennsylvania | 5.20% |

| Florida | 5.00% |

Liquid propane gas is also cleaner than oil; it is not a greenhouse gas. It usually costs a bit more than natural gas but is still fairly inexpensive.

It is quite common in rural areas of the United States, where Natural Gas pipes are not ubiquitous (Nebraska, Idaho, Oregon). It can be carried in pressurized containers.

Electric boilers are the most expensive ones, but they are also very clean, quiet and efficient. The installation and replacement process for an electric boiler is quite a bit easier and since they do not utilize open flames or a fire box they are considered less of a fire hazard.

Water Tube and Fire Tube Boilers

Boilers can be sub-categorized as fire tube or water tube types. This has to do with how the fluid distributed through the house is heated up.

Fire Tube Boiler

A fire tube boiler is basically a tank of water with a long tube bent back and forth running through the inside of the tank in the water. When the tank is filled with water the tube is surrounded with water on all sides. Now, one end of the tube goes up the chimney and the other end faces the burners.

Again, there is a tube open on both sides running back and forth through the tank of water. The tank is tightly sealed on the tube entrance and the tube exit so that water does not leak.

The burners blow heat into one end of the tube, and the heat goes through the tube heating the water in the tank. The heat and fumes go through the tube and are then released up the chimney.

The nice thing about this design (besides how elegant it is) is that there is a lot of the surface area of the tube in direct contact with the water. (That is why it goes back and forth – to maximize the surface area inside the tank surrounded by water.) The more surface area in contact with the water, the faster the water heats.

This is called a “Fire Tube” because there is fire (heat) inside the tube.

Water Tube Boiler

Water tube boilers work in the opposite way. They also have a long tube that bends back and forth, but it is filled with water and the burners fire outside the tubes. As the burners fire, they heat the air and the tubes, and that in turn heats the water in the tubes. The water (or steam) then circulates through the house.

This system could be described as taking a very long garden hose (in the case of heating this is metal piping) running it through the house, and filling it with water and attaching the ends together so that it is a continuous loop.

One section of the loop runs through the oven (heat exchange) which heats the water as it runs through. In order to keep the water in the oven as long as possible, the garden hose (metal piping) is coiled up inside the

oven (heat exchange).

In this type of boiler, the heating capacity is limited by the size of the heating chamber. Variations of this type of boiler are often used in industry settings.

This is called a “Water Tube” because there is water inside the tube.

Comparison of Fire Tube and Water Tube Boilers

The fire tube boiler fires and tries to heat the entire tank of water all at once. The water tube boiler fires and tries to heat a much smaller amount of water, that is the water in the tubes at any given time. The bigger the heating chamber the more water can be heated at once.

It turns out that water tube boilers are more efficient than fire tube boilers. In analyzing the boilers it makes a big difference if the denser liquid is inside the tubes or outside the tubes.

Water is much denser than hot air and gas. Since the water, the denser liquid, is inside the tube the water tube boiler has a higher overall heat transfer coefficient when compared to a fire tube boiler. The higher the heat transfer coefficient, the more efficient the system.

Comparison of Oil and Natural Gas Fuels

At one time oil boilers were ubiquitous, but now natural gas has taken much of their market share.

Oil, partially due to the method of transport, is more expensive than natural gas, but it burns hotter which means less of it can be used. On the other hand, oil boilers produce more soot and ash and therefore may require more maintenance.

With oil, however, the price fluctuates with the price of oil. There are some companies that allow the consumer to lock the price for the winter. If the price is low at the time of lock down, this can save you a lot of money. Some will let you wait until the price goes down to lock down. The cost generally fluctuates between $2.00 and $4.00/gallon.

Natural gas is considered cleaner than oil; it produces less greenhouse gas. And it is usually less expensive than oil or electricity.

Natural Gas Boiler vs Oil Boiler

Gas and oil boilers can both use a water tube or fire tube design, and they can both work with either steam or hot water. These different designs are available with either fuel type.

The Difference is in the Fuel

In comparing Natural Gas Boilers to Oil Boilers, one must be conscious of the cost of fuel. That will always be a factor, and it may be the biggest contributing factor to overall cost.

In general Natural Gas burns cleaner than oil, but now some manufacturers have a model that burns bio-diesel fuel. This biodiesel may be competitive in price with standard oil, but it burns cleaner and does not produce as much pollution. Oil boilers really always produce soot. This soot should be cleaned regularly so that efficiency is not impacted. There will also be an oil filter that should be changed regularly.

In terms of installation, there is a difference between the two. The exhaust from a gas boiler bypasses the chimney and can be directly vented from the boiler to the outside, whereas the exhaust from an oil boiler usually goes up the chimney.

Oil boilers may need more space around them so they can draw air in. Gas boilers most likely pipe air in from the outside.

Installation: Natural Gas and Oil

If you are considering installing a new boiler, it may be a good idea to get a ballpark estimate of what size you need.

How Much Power Do You Need?

There is a way to make a rough calculation for your BTU needs. Depending on the climate you live in, multiply the total square foot area by one of the following numbers.

After you determine the climate, choose low or high depending on the state of your insulation.

You can get a general feel for the quality of insulation by standing close to a window and feeling for drafts. If you feel air movement go with the high constant.

BTU Calculation

| Low Constant | High Constant | |

| Warm Climate | 30 | 40 |

| Moderate Climate | 40 | 50 |

| Mountain or Colder Climate | 50 | 60 |

| Really Cold Climate | 60 | 70 |

If you have a poorly insulated ranch style home, about 1666 square feet and you are living in a colder climate like rural Missouri then you would multiply your 1666 sq ft by 60 (high constant from our chart) and find that you need about 100,000 BTU. On the other hand, if you lived in northern Texas in a new house twice the size, 3,333 square feet, you could use a boiler of the same size (30 x 3333 = 100,000 BTU).

Prepare for the Installers

Preparing for the installers to come and install your new boiler is a nice thing to do. It may make the work go a bit faster and it will therefore be a bit less expensive, but regardless of the price you will most likely have happier installers in your home.

Clear the way to the boiler. Boilers are usually in the basement. If your basement is like some, the basement where the door doesn’t open all the way because of stuff packed in, you really should clear a nice path. The installers are going to need to bring a big, heavy boiler in and if there is stuff in the way they may not be able to (or they may just walk over your stuff). If there is a bulkhead, make sure that is clear.

If the boiler is in a dark, out of the way spot (in the basement), make sure there is a light of some sort. They will surely have flashlights, but a bigger light will only make their lives easier.

In case the floor is wet or flooded, you may want to take care of that before the installers come.

I personally always offer installers tea or coffee when they come. I prefer to have happy people in my house.

Boiler Installation

Installing a boiler is a big project. It is strongly suggested that you hire a competent team to install your boiler for you.

If you try to do it yourself, you should realize it’s a big, heavy piece of equipment that can be damaged fairly easily, and the overall system is quite complex.

On the other hand, installation is complicated, and prices are very difficult to estimate. The following chart is a compilation of rough numbers.

Average Boiler Installation Price

| Natural Gas | Oil | |

| National average cost | $8,362.00 | $6,500.00 |

| Average range | $5,000-$10,000 | $4,000-$9,000 |

| Minimum cost | $3,884.00 | $3,700.00 |

| Maximum cost | $16,158.00 | $11,000.00 |

An oil boiler is usually larger than a gas boiler, especially the newer high-efficiency gas boilers. The exhaust and moisture from the oil boiler may be damaging, so you have to line the chimney with some protection.

Space must be left around the boiler so it can pull fresh air into the system (as opposed to having fresh air piped in directly from the outside).

The boiler comes with a schematic with sizing and dimensions. Your installation team needs to know how to read the schematic and double check the installation against schematic.

Remember, with any heating system, fluid is moving through a system of pipes. Some places in the system are under pressure, some more pressure, and some less pressure.

Some pipes join other pipes with valves and air eliminators. The sizing of everything is important. A way to think about it may be to know that traffic systems are designed with the same principles as water systems. If there is a traffic jam, it can take a lot of time. If the water is flowing like it’s a traffic jam, it can cause big problems!

With oil boilers the consumer stores the oil on the premises, there must be a large oil tank installed typically in the basement or underground. Either way, the tank needs to be monitored for corrosion and leaks.

If you are installing a new system, make sure it is the right choice because it is really expensive and difficult to change!

There are a lot of suggested boiler maintenance tasks, many of which you can do yourself. Some people do, I would guess that most people have the boiler installed and never look at it again until something goes wrong.

If you do these tasks on a periodic schedule you are likely to see problems before something goes wrong.

Boiler Maintenance

Oil Boilers:

- Monitor the Oil Tank

- Clean soot buildup

- Oil Filter change

All Other Types of Boilers:

- Inspect and replace worn out parts

- Inspect fireside of heat exchanger

- Remove and wash the mesh

- Replace igniter, flame rod and gasket

- Adjust combustion

- Inspect Electrics for corrosion

- Clean and inspect condensate trap (if applicable)

- Inspect around and under for leaks

- Keep checking temperatures and error codes etc

- Always listen for unusual sounds and vibrations

- Inspect piping and vents for leakage or deterioration

- Inspect relief valves for leakage or deterioration

- Check condensate drain line for blockage (if applicable)

Installing a New Boiler In an Old System

Many HVAC professionals will charge between $50 and $200 to remove an old boiler, and many will simply remove it with the installation cost of a new boiler.

Installing a Gas Boiler in Place of an Oil Boiler Switching from Oil to Gas requires a number of updates to the system that can be difficult and costly.

The entire switch usually costs (if everything goes well) between $7000 and $9000, and can often run up to $15,000 to $20,000.

Some of the labor that may be necessary:

Labor Installing Gas in Place of Oil

| Labor | Approximate Price ($) |

| Gas line and meter installation | 1000 – 1500 |

| Gas lines from meter to house | 500-1,100 |

| Reline Chimney (stainless steel) | 100/linear foot |

| Replace Ductwork | 30-55/linear foot |

| Remove Oil Tank (above ground / below ground) | 500 – 1500 / 1,700 – 4,000 |

| Testing soil (for leakage) | 300 – 500 |

| Cleanup from leakage (as necessary) | 2,800 – 4,600 |

| Major ground cleanup (as necessary) | 12,000 – 95,000 |

How Much Does a Boiler Cost to Run?

The Natural Gas companies in America sell Gas by the “Therm”. This addresses the difference in billing in volume and not heating units. One Therm is the amount of Natural Gas needed to produce 100,000 BTU.

In volume, a therm is about 100 (96.7)cubic feet (CCF).

Of course, if we are talking about the volume of a gas, the temperature and pressure make a huge difference!

So, in this case we are calculating from Standard Temperature and Pressure (STP) of 0ºC (32ºF) at 1 Atmosphere of Pressure. The average cost in the USA is $1.028/Therm.

To put this together, if you run a boiler for 1 hour, it will cost you the number of therms X the cost per therm. A 100,000 BTU boiler uses 1 therm every hour. In this case the cost will be 1 therm X $1.028 = $1.028, and two hours would cost $2.056.

There are so many variables in this system that it is nearly impossible to estimate an ideal amount of time for the boiler to be running.

That being said, if we take an absolute guess and say the boiler is running 10 hours / day – it will cost $10.28 / day. If that is consistent throughout the winter months, 90 days, we are estimating a $925 heating bill.

In the winter of 2014-15 the average cost of heating in the USA was $1,851 in oil heat, but only $919 in Natural Gas.

Remember, oil prices fluctuate over time. Heating oil is usually less expensive in the summer months, and since you are going to store it anyway you may be able to take advantage of the drop in price.

There are companies that do not have the resources to deliver during the summer months and they will not be able to fill your order until there are more orders and the prices are higher.

Homeowners typically use 3.7 gallons of heating oil every day in the cold season. The current average consumer price of heating oil in 2020-21 is $2.35/Gallon, down from $3.07/Gallon in 2018-19.

If 3.7 Gallons of oil converts to 5.14 therms of oil (roughly equivalent to the 5 therms of natural gas we calculated above) then the daily cost of oil would be about $12.08/day at today’s prices. If that is consistent through the winter months, 90 days, we are estimating a $1087 heating bill.

We can also note that the average temperature goes up and down over the years. In 2014 the average temperature (over all the US for the whole year) was 52.54ºF, whereas in 2020 it was 54.36ºF.

In 2020-2021 the US reports that the average (across all of the US) consumer used about 60,000 CF of Natural gas, and about 509 Gallons of Heating Oil.

Just to check the numbers – 60,000 CF of natural gas is about 600 Therm, or about 6.66 Therm per day for the 90 winter season. The oil figure comes to about 5.66 gallons per day at the same time.

Average Consumption 2020-2021

| Fuel | Price | Therms | Amount | Cost/day |

| Heating Oil | 2.35/Gallon | 7.86 | 5.66 Gallons/day | 13.3 |

| Natural Gas | 1.03/Therm | 6.66 | 6.66 Therms/day | 6.86 |

And in 2014 the average usage is reported to be: natural gas was 60,700 CF and oil was 548.2 gallons.

Average Consumption 2014-2015

| Fuel | Price | Therms | Amount | Cost/day |

| Heating Oil | 2.35/Gallon | 8.46 | 6.09 Gallons/day | 14.31 |

| Natural Gas | 1.03/Therm | 6.74 | 6.74 Therms/day | 6.94 |